Compressed wood pallet production line

Automatic Wooden Pallet Machine | Molded Wood Pallet Making Equipment

Compressed wood pallet production line

Automatic Wooden Pallet Machine | Molded Wood Pallet Making Equipment

Table of Contents

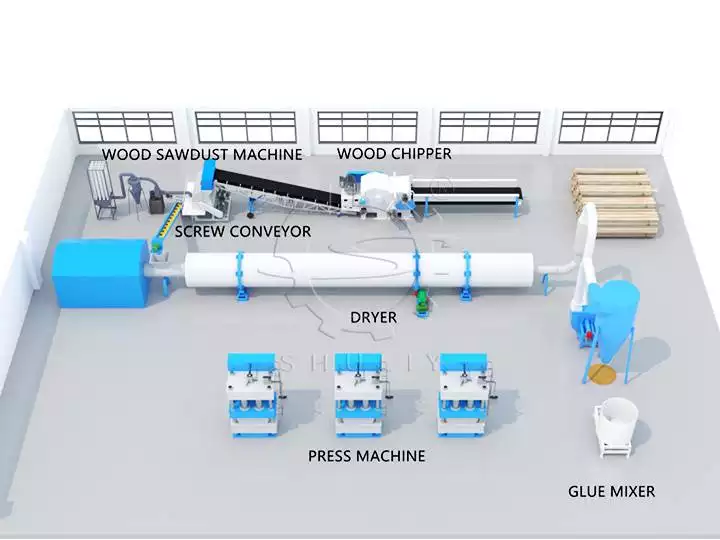

The compressed wood pallet production line is an automatic line to process wood chips, wood shavings, rice husks, etc. into quality wooden pallets. The wood pallets are widely used in logistics, warehousing, transportation and other fields.

Due to its eco-friendly approach, cost-effectiveness, and versatile applications, Shuliy molded wood pallet production line is popular in many countries.

If you’re looking for an efficient solution for biomass recycling, this molded wood pallet equipment line is your ideal choice.

Raw materials and applications for molded wood pallets

What raw materials can be used in the compressed wood pallet production line? What end product can be made? What are the applications of wooden pallets? Let’s explore together.

Raw materials for Shuliy automatic wooden pallet machine line include wood waste, sawdust, wood chips, wood shavings, rice husks, coconut shells, fibers, paper, etc. The size should be around 1cm.

The end products manufactured by the above raw materials are wood pallets. These wooden pallets have sizes of 1000*1000mm, 1100*1100mm, 1200*800mm, 1200*1000mm, etc. We can also customize it based on your needs.

These wooden pallets are produced to efficiently support a variety of loads, thus they are suitable for industries like delivery, storage, logistics, etc.

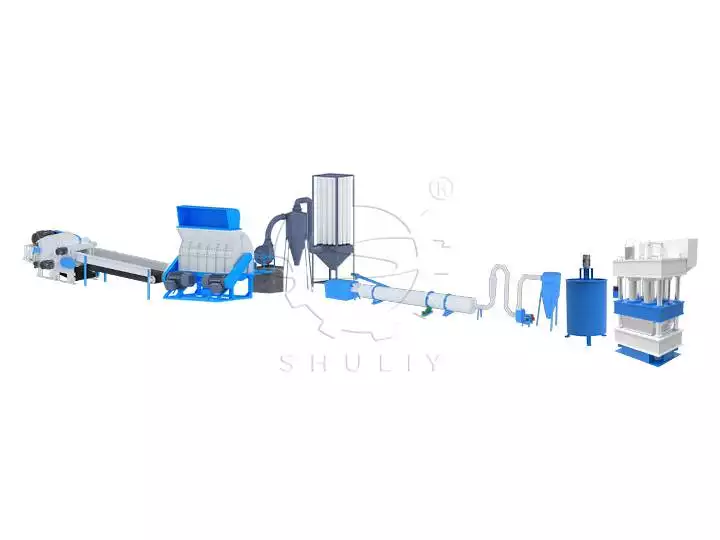

Components for compressed wood pallet production line

The compressed wood pallet production line includes drum chipper→hammer mill→dryer→mixer→wood pallet machine. Let’s introduce them one by one below.

Drum-type wood chipper for mass wood chips

The drum chipper is the first step of the wood pallet production line.

Because of the different sizes of raw materials, this machine is used to cut raw wood into small chips(25mm, adjustable).

Known for its high efficiency and precision, it chops wood evenly for consistent particles.

Hammer mill for fine sawdust

After chipping, you should further pulverize the wood chips to get finer sawdust around 1cm in size.

The equipment for this step is the hammer mill.

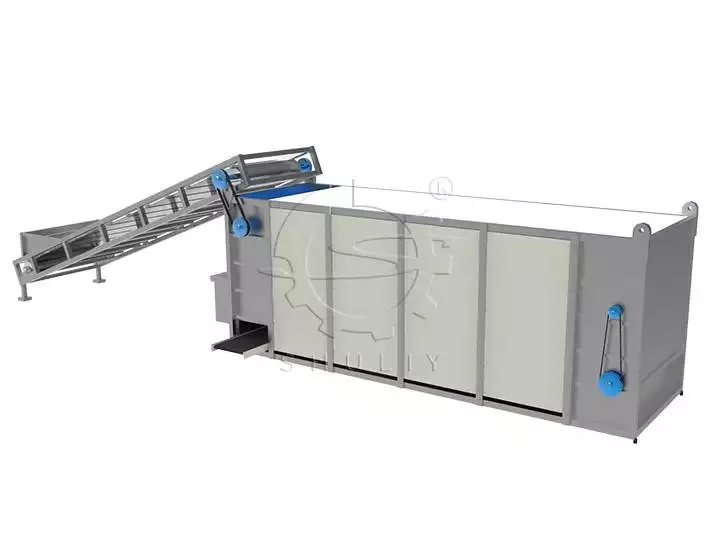

Rotary drying machine for sawdust

This sawdust dryer machine is used to remove sawdust moisture making it below 10%.

This helps to improve the strength and stability of the wooden pallets.

Glue mixer for wood sawdust & glue

This machine mixes the dried sawdust with glue to form a uniform mixture.

The mixture is important for the subsequent wood pallet making.

Molded wood pallet making equipment

Under high temperature and pressure, the compressed wood pallet making machine presses the mixture into the desired pallet shape.

It creates strong and durable wood pallets, suitable for loading a wide range of weights.

Advantages of pressed wooden pallet production line

- Output of one wood pallet requiring 4-5min. This capacity is only an estimate, and the time for making the pallets can be set on the power control cabinet.

- Fully automatic operation. The entire line is mechanically controlled, with a high degree of automation, reducing manual operations.

- Producing wooden pallets with 5-10t of static load and 3-5t of dynamic load. Our compressed wood pallet production line can make final products with high quality, meeting international standards.

- Environmental protection and energy saving. This line utilizes waste wood, reducing resource waste and meeting environmental protection requirements.

- Customizable wood pallet sizes and shapes. We customize them according to your needs.

- Wooden pallet sizes: 1000*1000mm, 1100*1100mm, 1200*800mm, 1200*1000mm, 600*800, etc.

- Wooden pallet shapes: different shapes by changing molds.

- After-sales service. We provide 24-hour online service, to ensure that equipment problems are solved promptly.

What’s the price of compressed wood pallet production line?

Curious about investing in a compressed wood pallet production line? Now we together check what affects line price.

The molded wood pallet making equipment line price varies based on production capacity, level of automation, configuration, sea freight, country, etc.

Also, factors such as customization, technical support and maintenance may further impact the final price.

The price of this automatic wooden pallet machine line starts at $10000, and even reaches $20000, or more.

If you want an accurate quote, you can contact us directly and we will provide you with an accurate quote based on your needs.

How to profit from making wooden pallets from waste wood?

With this compressed wood pallet production line, you can transform wood waste into durable wood pallets. The wooden pallets can be widely used in industries such as logistics and warehousing.

- Sell wooden pallets yourself.

- Cooperate with companies that need pallets for transportation and storage.

This investment not only generates revenue, but aligns with sustainable practices and can create immeasurable value.

Eagerly await your inquiry!!

Are you looking for creative solutions to turn waste into value? Contact us to find more information about the biomass recycling line for profits!

Compressed wood pallet machine

Compressed wood pallet machine is specialized equipment for manufacturing compressed…

Hot Product

Continuous charcoal furnace for sale

Continuous carbonization furnace is specially used to convert…

Wood sawmill machine for log cutting

Wood sawmill machine is designed to process logs…

Charcoal machine for coconut shell charcoal manufacturing

Coconut shell charcoal making machine is designed to…

Barbecue charcoal ball press machine

Shuliy charcoal ball press machine is for pressing…

Hoist charcoal furnace for wood logs, bamboo coal

Hoist carbonization furnace is capable of carbonizing logs,…

Round & cubic shisha charcoal tablet press machine

This shisha charcoal machine is for the efficient…

Drum wood chipper machine for chips production

Drum wood chipper machine is designed to chip…

Vertical wood peeling machine for tree debark removal

Wood peeling machine is designed to remove the…

Continuous drying machine for BBQ charcoal

The briquette dryer machine is used for BBQ…